GMT Benelux BV

GMT Benelux is expert in the field of vibration challenges. Since the company has been established in 1987, it’s our goal to reduce and prevent unwanted vibrations by innovative and high-quality solutions. GMT is short for Gummi Metall Technik, the technique to control vibrations by applying products made of rubber and metal. From our site in Venlo, The Netherlands, we support our customers with a team of 20 employees with logistical and technical support, measurements and calculations.

By reducing and preventing unwanted vibrations, we increase the performance and comfort for people exposed to vibrations. Our solutions will increase the stability of (production) processes, increase efficiency and reduce wear and tear. Together with our customers we build sustainable solutions and reduce lifecycle cost.

GMT Benelux offers a wide range of standard products and develops tailor made solutions. Our rubber-to-metal products are applied in a wide range of applications, varying from Machine Buidling to Railway Vehicles and from Special Vehicles to High Tech.

“GMT Benelux B.V. (Algemeen Directeur)” Academy LINK

“GMT Benelux [vervolg 1] Academy LINK

“Kennis delen in de praktijk bij GMT Benelux BV Academy LINK

Deelname KSC MTC 2023 LINK

Machine Building

Our experience with machine building and drive technology has been built up from the start of GMT Benelux in 1987. For more than 30 years we offer support for vibration challenges, for both simple and complex issues. Depending on the machine specifications and the specific problem definition we are happy to help you to select the right damper.

We can assist to isolate or damp unwanted vibrations. In specific applications vibrations are very relevant and thus desired. For example, compactors for concrete manufacturing, vibration equipment for construction or sorting equipment for seeds. In case you want to isolate, damp or arouse vibrations: GMT Benelux offers the dedicated support, regardless the application.

Annemarieke Custers 310773872556 sales@gmt-benelux.nl

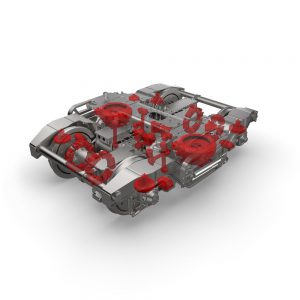

Railway Vehicles

When trains, trams and subway vehicles are purchased, maintenance and overhaul are important drivers for ‘Cost of Ownership’ and ‘Cost of Operation’. Since decades GMT delivers innovative solutions for railway vehicles. For railway vehicles GMT’s focus is mainly on the primary and secondary suspension of the bogies. To keep the vehicles in optimal condition, it is important to have a clear view on the condition of the rubber - metal parts. By supporting periodic, scheduled inspections, we can give a clear insight in the timing for replacement of the parts. By supporting our customers proactively, we can prevent unforeseen cost and contribute to a higher availability of your vehicles.

Thinking about a sustainable future

Together with our customers we build sustainable solutions which save costs on short term as well as in the long run. In addition, we want to contribute to the comfort for the users of the vehicles and their environment. When vehicles are in good condition, the equipment has less wear and tear. The users and their environment will be less impacted by vibrations and noise.

Jimmy Withoot 0031773872556 sales@gmt-benelux.nl

Special Vehicles

We support controlling vibrations in, for example, the cabin and chassis of specific vehicles (e.g., crash tenders, AGV’s, road sweepers and vehicles for agriculture). Damping and isolating vibrations results in specific benefits:

1. Less wear and tear

2. Better comfort

3. Lower cost by optimal maintenance and overhaul.

Your vehicles in excellent condition

In case you invest in new special vehicles, cost of maintenance and overhaul are very important because of the contribution to ‘Cost of Ownership’ and ‘Cost of Operation’. Over the last decades GMT provides innovative solutions for special vehicles. To keep vehicles in good condition, it is very important to have a clear view on the condition of the rubber-metal parts. Through periodic scheduled inspections we can support you to get a clear view on when specific parts need to be replaced. By supporting our customers in a proactive way, we prevent unforeseen expenses and unscheduled maintenance, and we contribute to a higher availability of your vehicles.

Annemarieke Custers 0031773872556 sales@gmt-benelux.nl

High Tech

The smallest details make the difference

GMT delivers solutions for machine building since decades.

The focus for the High-Tech industry lies with passive damping of vibrations in high precision applications.

For mechatronic systems the requirements for accuracy of positioning become stricter over time. Vibrations can cause challenges to reach a certain accuracy.

The dynamics of a system can be effectively improved by applying damping. This can be achieved actively and passively. In close cooperation with partners, a passive damping methodology has been developed for the High-Tech industry, based on polymers. Specific requirements for applications in the cleanroom are taken into account.

Industrial packaging

Vibration dampers are increasingly being used in packaging in order to absorb shocks and vibrations. This special packaging ensures that the machines arrive at their destination undamaged.

Our engineers provide support with the design, calculation and measurement of packaging. We also supply a range of products from stock, which we have developed especially for industrial packaging for High Tech equipment.

Roy Tervooren 0031773872556 sales@gmt-benelux.nl

GMT Benelux BV

Company info

List of specifications

- 1 - 25

- Component supplier, Manufacturing Companies

- Local, Nationally, International