High Tech Dummy Frame

MBD stands for:

Model Based Definition (or 3D-PMI)

Model-based definition is an approach to create 3D models so that they effectively contain all the data needed to define a product. With MBD, the model becomes the source authority that drives all engineering activities. This model may further be used downstream by suppliers and across organizations within an enterprise.

Wikipedia

PMI stands for:

Product & Manufacturing Information

Product and manufacturing information (PMI) is used in 3D CAD and/or

collaborative product development systems to convey information about the design of a product’s components for manufacturing. More specifically, PMI conveys information such as geometric dimensioning and tolerancing (GD&T), 3D annotation (text), surface finish and material specifications.

SIEMENS

FROM 2D DRAWING TO 3D MODEL

2D drawings:

A technical drawing describes the requirements that a designer sets for the workpiece. These workpiece specifications are committed by means of 2D drawings.

3D Model with PMI:

A technical model describes the requirements that a designer sets for the workpiece. These workpiece specifications are committed by means of a 3D model with the PMI information.

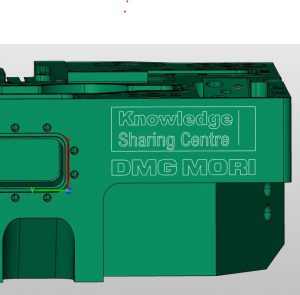

In collaboration with ASML and DMG Mori, the Knowledge Sharing Center has created a High-Tech model that can be used freely by anyone to realize the start-up to MBD and PMI.

“High-Tech Dummy Frame” files:

#Questions or comments

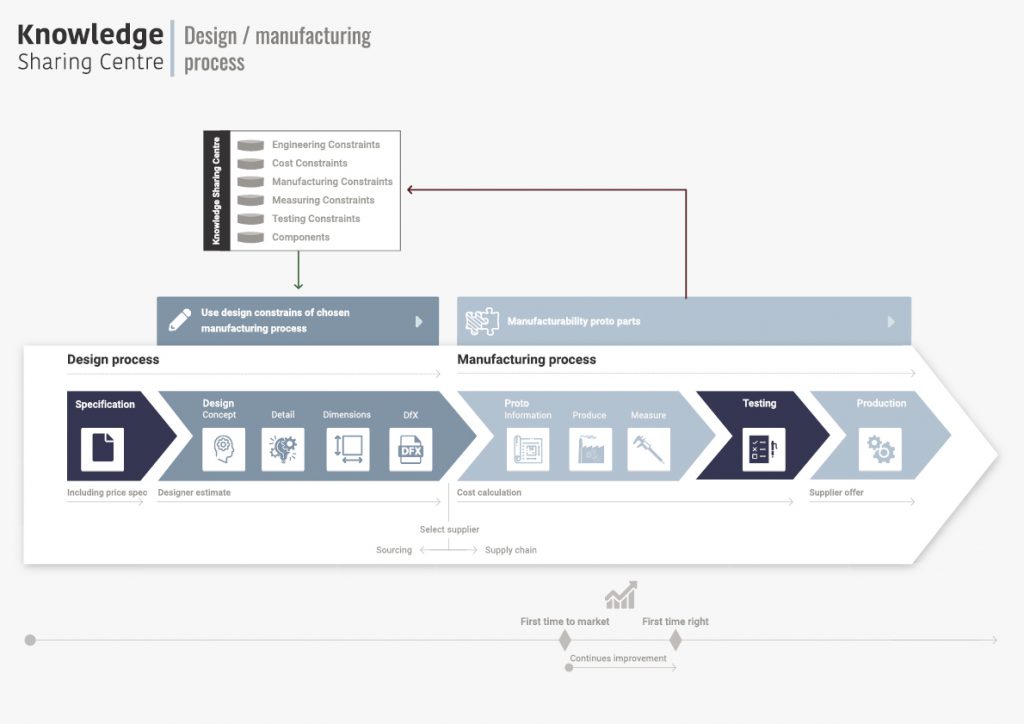

Design and Manufacturing Process

Idea phase

Idea phase

In this phase, a functional idea is made based on the specifications.

How

The way this is done is very different. Some start sketching to come up with an idea, but sometimes it can also be a brainstorm. It is important that this phase gives an idea of how we will functionally solve a given specification.

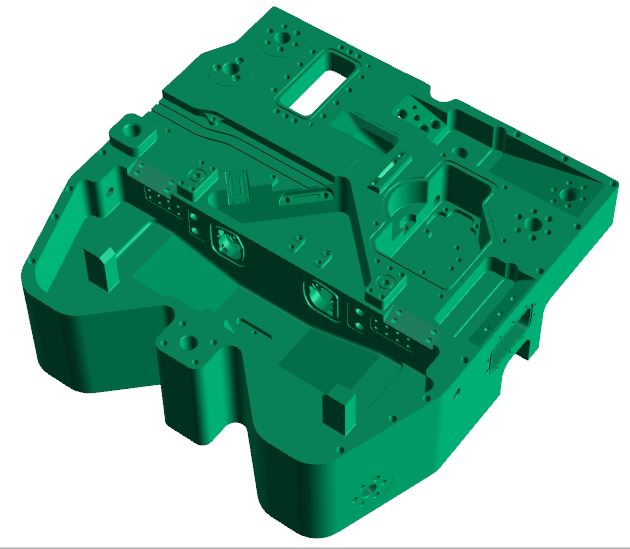

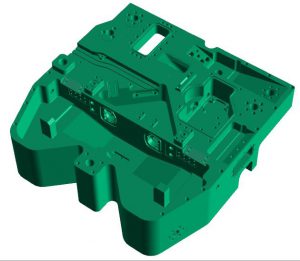

Detail phase

In this phase, the functional idea is converted into detailed information.

How

For this, a CAD program is used to generate a 3D model. We also call this a 3D Solid. Every detail is introduced into this model so that we can get a good view of whether all functionality is accommodated. Inserting this 3D solid into the 3D solid assembly provides even more insight into whether everything has been included in the phase.

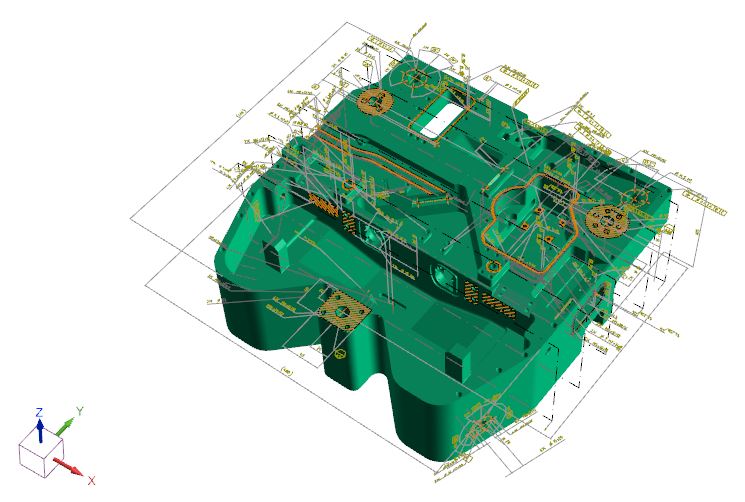

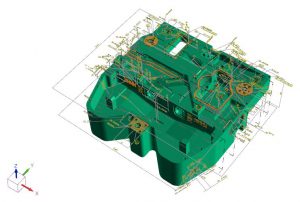

PMI phase

During this phase, all dimensions are entered into the 3D model.

How

Previously, we used 2D drawings to transfer the dimensions of a product to the supplier who made the products. In the digital world we want to add these dimensions to the 3D model. This not only takes digitization a step further, but now we can also communicate with each other about the manufacturability of a product at an earlier moment. We no longer have to wait until the 2D drawing is completely ready, but we can talk to each other when we have the 3D model ready or partially ready.

Program phase

During this phase, the machine tool program is created. Partly automatic, partly controlled for the specialist.

How

From the 3D model, it is checked which processing is needed with which machine to arrive at a complete product. Depending on the machine that is used, the right software program will also have to be created to make the machine work efficiently.

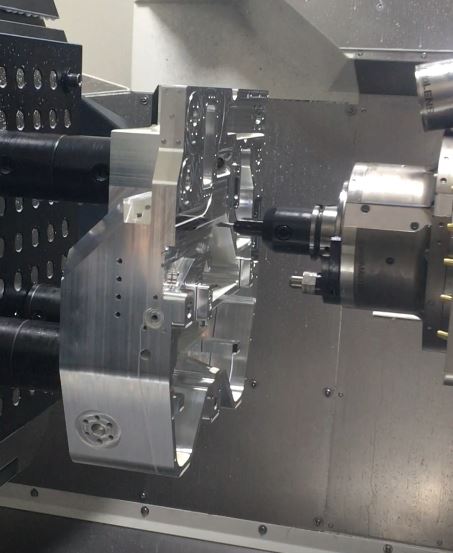

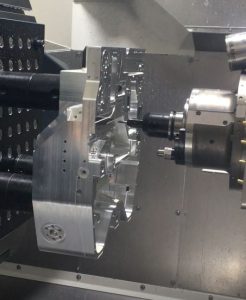

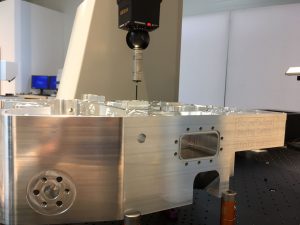

Manufacturing phase

During this phase, the product is processed.

How

All operations necessary for this product are performed. At the end of this phase we will have a completely processed product.

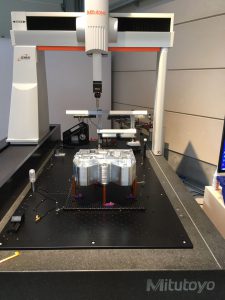

Measure phase

During this phase, the product is measured to see if all dimensions fall within the limits.

How

This process can also be automated by adding the dimensions to the 3D model. The software then generates the program to measure the product.

Series production phase

During this phase, the series production starts.

How

After all phases have been carefully completed, the production of the series can be started.

Pictures

Precision Fair 2023

The produced example product was shown on the stand of the Knowledge Sharing Centre. There was a lot of attention to watch it.

The free download of the file was appreciated and has already been used a lot. This will take us further to understand even better the attention in order to improve the process.

Supplier responses

Download files and relevant items

Files:

High Tech Dummy Frame Download Zip file

Relevant items:

Presentation Precision Fair 2022 from Leo Broers ASML. LINK