Electro Chemical

Electro Chemical Machining (P)ECM

INDEX:

Manufacturing process explanation

↑

The process in detail

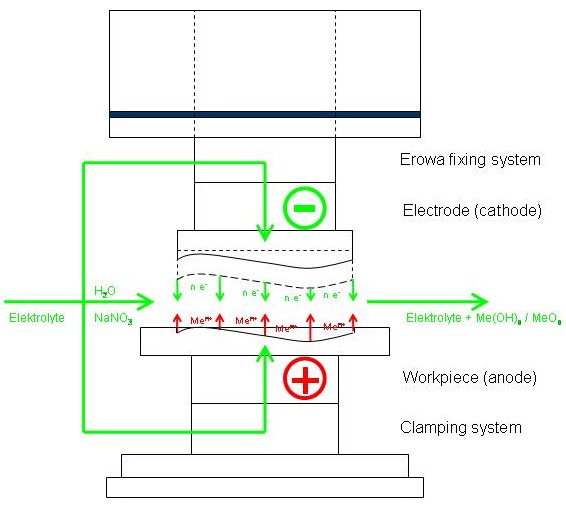

During the pECM process metal is dissolved from a workpiece with direct current at a controlled rate in an electrolytic cell. The workpiece serves as the anode and is separated by a gap (which can be as small as 10 µm) from the tool, which serves as the cathode. Therefore, the work piece and the work tool do not touch in any moment. The electrolyte, usually a salt solution in water, is pumped under pressure through the inter-electrode gap, thus flushing away metal dissolved from the workpiece. As the electrode tool moves towards the work piece to maintain a constant gap, the workpiece is machined into the complementary shape of the tool.

PECM resembles electroplating in reverse: instead of adding material, pECM removes it. The technique can also be described as the opposite of electrochemical or galvanic coating or deposition process. Due to the non-contact principle of the process, no mechanical or thermal stress is exercised on the work piece.

Material removal rate (MRR) is an important characteristic in evaluating the efficiency of the non-traditional machining processeses. In pECM, material removal takes place due to the atomic dissolution of the work material. In addition, unlike the previous generations of pECM machines, the current pECM technique benefits from pulsating power supply and a vibrating axis. This concept enables processing even products with a minimum process-gap of just a few micrometers, as well as shaping complex forms both internally and externally.